+1(206) 639-2889

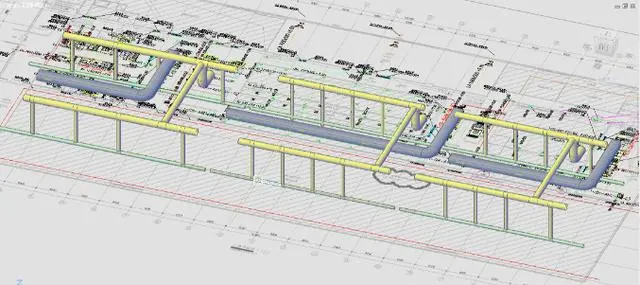

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Founded in 1981, Meyer Corporation is one of the largest cookware and kitchenware marketing and distribution companies with headquarters in the United States. Meyer affiliate factories comprise the world’s second largest cookware manufacturing operation, producing over 100 cookware lines distributed in over 30 countries. The factories employ more than 6,400 people, manufacturing more than 42 million pans per year on average.Meyer Thailand manufacturing center founded in 1996, locates in Chonburi Thailand, over 100,000 m2.

We are proud that we can serve Meyer Thailand's manufacturing centre and provide air solutions for the canteen and workshops. As we know, Thailand is in tropical climate zone, the temperature is around 24~30℃ and indoor temperature is much higher. The canteen is a low space with a high density of people. And there is no building insulation for this facility. All of these makes temperature inside the canteen is over 36℃. So, the A/C system including the air duct system must cool down the whole area 1st / 2nd floor rapidly and make workers who eat here comfortable. Meanwhile, Safety First and fire proof performance of the air duct system must be considered. And the roof load of this building is limited and can afford lightweight.

After knowing these essential needs from Meyer Thailand, we provide a system that is much better than traditional duct, supplying the cool air evenly through both fabric permeability and laser cutting orifices without condensation issues. First, we introduce Nanosox N series fabric duct systems made of inherent permeant Class B fire retardant raw material and provide the longest 15 years warranty in this industry. Second, we employ high fabric permeability to make sure the duct system brings down the indoor temperature rapidly. Third, we strictly control the orifice size and get end air velocity at 1.5 meters height no more than 0.5m/s which can make workers feel comfortable and cool with just a little draft. And the weight of the DurkeeSox® system is just 2.5% of the GI duct, can match the limited roof load perfectly as well as easy installation. Much simpler DurkeeSox® system totally replaces the conventional system including air ducts, air diffusers, and insulation material. Lightweight, easy transportation and installation, very short installation time, all these reduce the overall cost too.

Workshops

Same as the canteen, there is no building insulation for buildings of workshops. It is extremely hot in the workshops with high humidity. And roof load of all buildings is limited which can afford only an air duct system of lightweight. The high density of people, Safety First, and fire proof performance of the air duct system must be considered, too. The only difference between workshops and canteen is that workshops are high space and air duct systems mainly supply cool air to workers without condensation issues.

First, we still introduce Nanosox N series made of inherent permeant Class B fire retardant raw material and provide the longest 15 years warranty in this industry. Second, we employ micro-permeability which effectively prevents condensation meanwhile reduce the cool air at the high space to be within 5% of total air volume. Third, post air distribution is adopted, orifices are placed along the production line and post, concentrating 95% cool air to cover every post with end air velocity around 0.8~1m/s which can make workers feel comfortable and cool with strong draught.

DurkeeSox® system is light in weight and meets a limited load perfectly. Easy transportation and installation, very short installation time, all of these reduce cost. DurkeeSox®system has been widely applied in various permanent and temporary applications such as supermarkets, sports, public facilities & events, automobiles, logistics, etc. It`s been consistently approved by countless renowned clients in more than 32 countries and regions. all of these successful applications have made DurkeeSox® one of the international leading brands.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية tiếng việt

tiếng việt Svenska

Svenska