+1(206) 639-2889

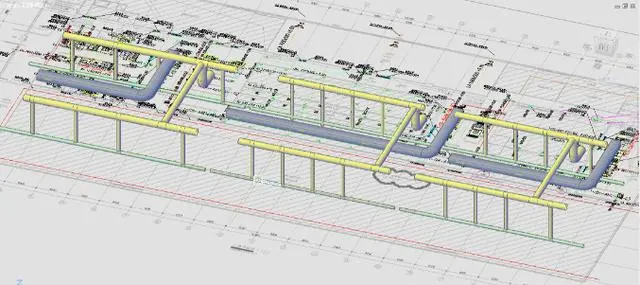

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Kraft Food, as one of the largest food producers, is one of the pioneer adopters who turn to DurkeeSox premium fabric air dispersion system in various production facilities to address their challenging HVAC and makeup air projects. After seen many success stories in Kraft China division, Kraft Canada Biscuiterie Montreal Bakery is turning to Durkee for fabric air dispersion solution to address the makeup air project in their biscuit production line.

Continuous Improvement Engineer David Binet and Senior Loss Prevention Specialist Joanne D'Abreu were facing quite some challenges when they tried to implement a new makeup air unit in the biscuit baking line. Among them are complex production lines, piping, and equipment layout, challenging large airflow in the makeup air system, and limited space to arrange the ductwork.

Having learned the DurkeeSox success story in Kraft China, Kraft Canada started to consider the potential benefits fabric air dispersion system brings to the table. The most significant ones are substantial cost savings and better air distribution. The fabric duct system offers the same linear air dispersion only the costly linear vent systems can deliver a fraction of the cost. Other benefits of DurkeeSox fabric ducts include low maintenance, easy installation, easy cleaning, and resistance to dust buildup. As David Binet, explains, “For an exothermic process like ours, using fabric ducts and induction to increase the amount of fresh air in the plant and reduce heating costs will be beneficial.”

In this application, the jet streams from customized linear vents on the fabric ducts draw the existing warm air close to the ceiling and mix it with cold fresh air, allowing the facility to operate at lower, more even temperatures without consuming extra energy to heat incoming air. “We can bring in air at temperatures as low as –7°C without condensation,” says Binet. In addition, the comfort level for occupants has increased noticeably.

Because of the baking oven line in the facility, fire safety is on top of the team’s mind. After reviewing extensive safety certification and test reports from different vendors. The team concluded that only NanoSox fabric from DurkeeSox is approved to be used in this project.

Experienced dramatically reduced energy consumption, Mr. Binet recommends that other companies in situations similar to Montréal Bakery consider DurkeeSox fabric dispersion system as an alternative to conventional air diffusion systems, if feasible.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية tiếng việt

tiếng việt Svenska

Svenska