+1(206) 639-2889

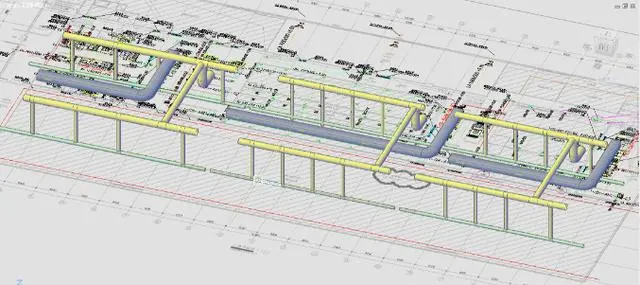

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Due to the problems and inconvenience caused by the use of traditional iron air duct, the combination of traditional iron air duct and fabric air duct began to be applied in central air-conditioning in large space. Such combination will not only achieve the purpose of environmental protection and energy saving, but also exert the effect of central air-conditioning to the maximum extent. Now let's talk about the differences between the two duct systems in usage and performance.

(1) The convenience of construction

Galvanized iron air duct is suitable for large size processing, and the mechanical processing of it is convenient, but the processing of small-size galvanized iron air duct is slow and takes a long cycle because it is not inconvenient to use mechanical equipment. In addition, it is difficult to control the installation precision during the construction of galvanized iron air duct; other accessories of the same size are not easy to produce; the installation is difficult and requires high requirements for construction personnel.

The installation of fabric air duct is simple and it does not need special processing equipment. The construction of fabric air duct is fast and has relatively low requirements for construction personnel, so choosing fabric air duct can save the installation time to the greatest extent.

(2) The energy-saving effect

The coefficient of thermal conductivity of fabric air duct is much lower than that of galvanized iron air duct. The coefficient of thermal conductivity of galvanized iron air duct (adopting 20 mm rubber insulation materials) reaches up to 0.035 to 0.043 W/(m.K), and when the insulation material of galvanized iron air duct is exposed to air for a long time, the phenomenon of moisture absorption will occur, which greatly increases the coefficient of thermal conductivity of galvanized iron air duct.

The fabric air duct does not need any insulation material, and the opening position of ventilation is very flexible and decided through accurate calculation, which can make the utilization rate of the draught fan reach over 90% and realize the best energy-saving effect.

(3) The fireproof performance

Galvanized iron sheet is a kind of inorganic material with good fireproof performance. It is an A-class non-combustible material. However, rubber and plastic insulation materials are often used outside it, which greatly reducs the fireproofing grade of galvanized iron air duct.

Fabric air duct has been tested by the authority as a B1 class permanent fire-proofing material, which can greatly improve the fireproof performance.