+1(206) 639-2889

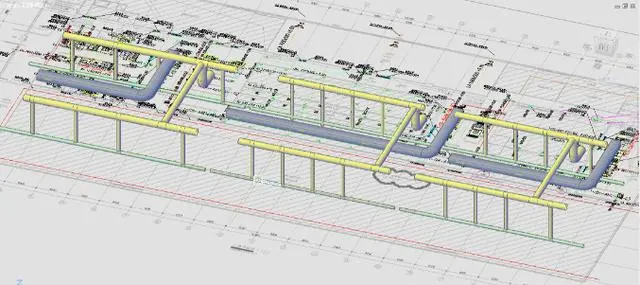

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

With the rapid development of the automotive industry, there have been many problems in the workshops of automobile factories. Due to the complex internal space structure, numerous mechanical equipment, a large number of operating personnel, and a large amount of production waste, there are some problems when using central air conditioning. The application of Durkeesox fabric air ducts just demonstrates the advantages of using them in automotive workshops.

The advantage of temperature uniformity in Durkeesox fabric air ducts

Most production workshops have large and complex roof structures, which have posed unprecedented challenges to air conditioning engineering. As it is not a fixed workstation, it is impossible to use a point-style workstation to layout air outlets.

At the same time, a large number of brackets, steel beams, suspensions, cranes, and other obstacles make it impossible to carry out the continuous layout of air ducts along the workstation line. Directly supplying air from the high space above the obstacle makes it impossible to guarantee the effect and accuracy, and also increases the load significantly.

The application of Durkeesox fabric air ducts solves this problem. This type of permanent flame-retardant fiber from the United States is woven into a fiber fabric air duct, which achieves truly uniform air distribution through the surface fiber infiltration and continuous hole jet two unique air supply modes. The continuous small holes cut by laser on the surface can form a continuous linear air supply belt, effectively solving the need for air supply along the workstation line.

The advantage of installation and suspension of fabric air ducts

Durkeesox fabric air ducts are extremely light in weight, with a surface density of only 290g/m², equivalent to 1/40 of metal air ducts. The structural load-bearing capacity can be almost negligible, so they can be installed above the workstation line below various obstacles.

Only simple tools are needed during installation. After fixing with wire ropes (or rails), the fiber fabric air ducts can be directly hung on the wire ropes (or rails). This not only saves labor during installation but also significantly reduces the top load-bearing capacity and construction period.

Thus, the two major challenges that traditional air duct systems cannot solve are resolved, perfectly solving the air conditioning air supply problem in production workshops.

The excellent air quality advantage of fabric air ducts

Production workshops occupy vast space, and the internal air is not easy to replace with fresh air. Therefore, the air quality in the workshop is a major hidden danger affecting workers' health. Especially for long-term operation, the harm caused by polluted air is more terrible than a high-temperature environment.

Designers have tried various solutions, such as adding new fans, adding air purifiers to the return air duct, and even providing workers with anti-gas masks, but these cannot fundamentally solve the problem.

Although the new fan brings in outdoor fresh air, and the air purifier makes the air entering the return air duct cleaner, the fundamental problem is that the traditional metal air ducts have already become dirty, and bacteria breed inside, making it difficult to guarantee healthy air and even having the opposite effect.

The advantage of easy cleaning and maintenance of fabric air ducts

Due to the structural characteristics, cleaning has always been a major problem for traditional air ducts. After long-term use, the inside of traditional air ducts is dirty, with serious dust accumulation, rust, and corrosion. Currently, there are two cleaning methods, manual cleaning and robot cleaning.

Due to the structural characteristics, Durkeesox fabric air ducts have the advantage of being easy to clean. After using for some time, the fabric air ducts can be directly taken down and put into an industrial washing machine for cleaning. After washing them clean, the Durkeesox fabric air ducts can be hung again, which is convenient and inexpensive.

The shrinkage rate of Durkeesox fiber fabric air ducts is only 0.2%. According to Chinese industry cleaning standards, it can be cleaned every two years and used for 100 years. Even if it is cleaned once a year, it can still be used for 50 years.

The energy-saving advantage of fabric air ducts

Due to the material and design characteristics, Durkeesox fiber fabric air ducts only need 150Pa static pressure to meet the air supply demand, and the resistance along the way can be negligible, greatly reducing the operating costs. After long-term use, it saves a lot of expenses.

The cost-effective advantage of fabric air ducts

The Durkeesox fiber fabric air ducts have a variety of colors and are beautiful and eye-catching after installation, injecting vitality into the workshop.

Moreover, the surface of Durkeesox fiber fabric air ducts can be customized to the enterprise's logo, which looks more unified, coordinated, and solemn, shaping the new image of the enterprise.