+1(206) 639-2889

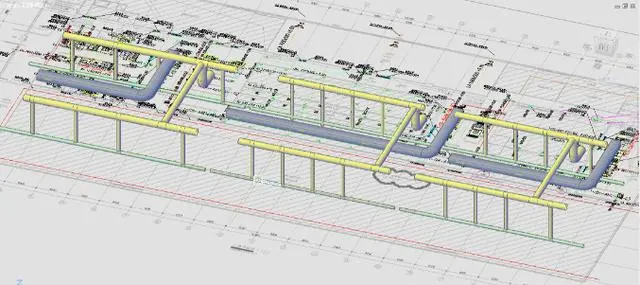

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

In recent years, the air distribution system of the air duct (also known as fiber fabric air duct has become more and more popular with users. The application range of the air duct has been spread to various industries from the earliest application in the food industry. The reason why the air duct can replace the traditional metal duct in many fields is inseparable from its own advantages.

One of the advantages of air ducts: lightweight

Since the air ducts and the metal air ducts are made of completely different materials, the advantage of self-weight is obvious. The use of the air duct system can greatly save the engineering installation cost, transportation cost, and safety performance is also brilliant. However, many users have a misunderstanding about the thickness of the air duct material. They always think that the thicker the material is, the better and stronger it will be. In fact, it is not true. The main function of the air supply duct is to transport the hot and cold air in the duct, and the transport power of the wind is the pressure of the fan. The air pressure of the general air conditioning unit will not exceed 2000pa. As the experiment shows, after being tested for pressure, it has been proved that the air duct made of the fabric of 100g / m2 quality can withstand more than 2000Pa pressure.

So how much the thickness of the fabric duct material would be optimal? Under the condition of satisfying the pressure resistance and tear strength of the air duct, the lighter the better. Generally, 140g / m2-220g / m2 is suitable, especially in food factories, clean workshops, and other environments that require frequent cleaning, the lighter, and thinner, the more convenient to use.

It has been proved by practice that the thicker the material of the air distribution pipe is, the lower the difficulty of design is, which can conceal the phenomenon of the vibration of the air distribution pipe caused by insufficient design experience in some fabric duct manufacturers. However, there is no real benefit to the user, and the real advantage of the air duct is lost, which will bring great difficulties to the later maintenance.