+1(206) 639-2889

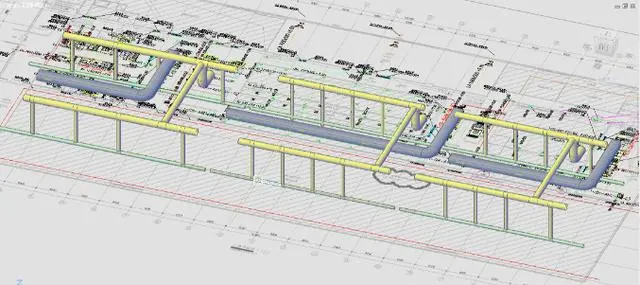

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Typically, duct systems hidden in ceilings and walls must be made of metal to comply with fire codes. However, fabric air ducts are the ideal choice for open architecture ceilings, in other words, when they are visible.

Any use of fabric will always involve its integration with metal in terms of pullout wires, transition ducts, clamps, and adapters between mechanical equipment and fabric ductwork. Metal ducts are also used in enclosed spaces to provide fabric air duct in exposed areas.

One important difference is weight. Fabric air ducts can save tens of thousands of dollars for an existing industrial building with ventilation or air-conditioning when compared to metal ducts due to a weight reduction of 90% even post HVAC.

The roof structure of an original building may be easily supportive of fabric air ducts, but hundreds of tons of metal ducts will require structural protection for reinforcement.

A good reference is a fabric air duct with a 60-inch diameter that weighs only 2 pounds/linear foot (Even with the heaviest hanging system and hemispherical ribs). Plus, given that fabric ductwork is installed 75% faster than metal ductwork, substantial labor savings can be realized.

Because production lines are frequently moved and reconfigured. Moving suspended metal ducts for a reconfiguration is expensive, but fabric can be inexpensively dismantled and reinstalled in a matter of a few hours.

From the perspective of logistics and installer safety, high ceilings are also a major application for fabric air duct. For example, cold storage facilities are currently trending towards taller designs to obtain building value in a small surface area.

Recently, a pharmaceutical cold storage required pipes to be hung on a ceiling 90 feet high, beyond the limits of traditional building elevator equipment. The lightweight and easy-to-work-with fabric air ducts provided a safer environment for the suspended specialists who had to install 20,000 linear feet of 68-inch diameter ductwork.

A more significant benefit of fabric air ducts is the micro-perforated design of the fabric ductwork, which provides suitable temperature uniformity by venting air through hundreds of micro-pores, as opposed to the traditional metal/slip-joint method.

Therefore, laboratory settings are particularly advantageous for fabric ductwork because they require evenly distributed, gentle air dispersion without airflow that is unhealthy for humans and lab animals alike.

The inherent high-speed airflow in metal ductwork design can also disrupt the exhaust of ventilation hoods, causing stratified air to spread pollutants.

Fabric-based air dispersion is also beneficial in indoor swimming pools where high dew points, condensation and the volatile environment of airborne chemicals can corrode metal ducts even when coated and insulated. Fabric air duct systems do not corrode and the choice of permeable materials prevents condensation as the air flows through the fabric.

Temporary tents for parties, golf tournaments, air shows and other outdoor events are increasingly using large-tonnage packaged units that provide HVAC through fabric ducts suspended from the ceiling.

There are dozens of examples where fabric air ducts are better than metal ducts in terms of material cost, quick project requirements, cleanability, labor savings and other advantages.

Contractors should weigh the advantages of fabric ducts versus metal ducts for each ventilation project in order to provide their customers with a choice of solutions.

Contractors can learn more about duct project design and installation from major duct manufacturers, and companies are available to provide instructional videos, engineering assistance and customer support.