+1(206) 639-2889

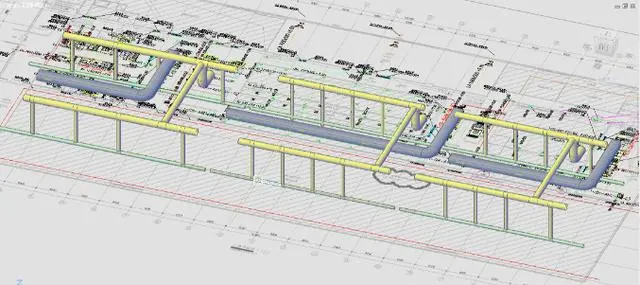

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

2024-03-14

Durkee textile air ductwork has been applied in the automotive plant since 2008, from industry benchmarks, foreign-invested factories to domestic-owned factories, and from OEM to other automotive accessories producers. So far, all major engineering projects or benchmark enterprises in automobile manufacturing plants have chosen Durkee flexible fabric air dispersion system. Durkee has a group of famous users worldwide, such as Volkswagen, General Motors, Ford, Renault, Fiat, Tesla, Toyota, Honda, Nissan, Audi, Mercedes-Benz, FAW, SAIC, GAC, Dongfeng, and Geely, etc.

By 2015, all automobile manufacturing industry projects only used Nanosox fabric ducts as the secondary air supply duct with unique properties, such as low space position line or spot air supply for energy-saving, environmental protection, easy installation, and oil resistance, etc. Since 2016, the insulated fabric air duct, which is the unique research and development of Durkee, has been fully promoted in the market.

It has been successfully applied as the primary air supply duct system for automobile manufacturing plants, including Jiangling, General Motors, Faurecia, FAW Toyota, BAIC, Ford, Dongfeng Honda, Geely, GAC Honda, and other projects.

Compared with commonly used traditional GI ducts, the advantages of the insulated fabric duct are more obvious:

The insulated fabric ducting solution has a 100% factory prefabrication rate and on-site modular assembly, which is light in weight, requiring only slide bars or cable suspension, with zipper connection, greatly improving the quality of the project, shortening the construction period, and reducing the overall cost of the project.

The insulated fabric duct is composed of duct layer, an insulation layer, and an outer insulation layer, achieving a dual-layer insulation effect.

The integral composite insulation material has an infinite vapor resistance factor, which can effectively prevent water vapor penetration, maintain the initial thermal conductivity coefficient, and have a better insulation performance. The thermal resistance value is comprehensively improved. The Durkee fabric duct can effectively reduce cold and heat loss during the air transmission process.

Different from the easy shearing and pressure deformation of rectangular metal ducts, the insulated fabric duct system adopts circular and elliptical shapes.

The insulated fabric duct can reasonably convert internal pressure into transverse tensile force on the duct wall, which can withstand 3000Pa-5000Pa or more pressure, far higher than the applicable range of traditional ducts below 2000Pa.

The insulated fabric duct system has been successfully applied in more and more primary air supply duct systems and return air duct systems. Durkee has become the leading supplier in the global fabric duct industry with a full range of professional solutions.