CALL US

+86-27-59370099

+1(206) 639-2889

+1(206) 639-2889

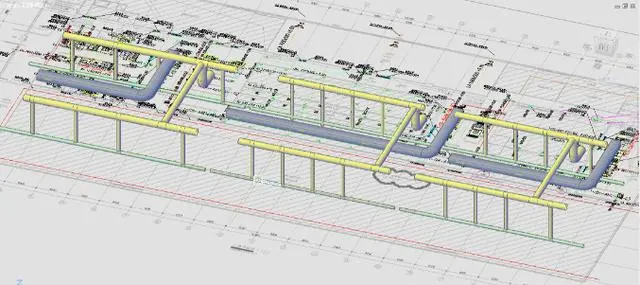

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

BIM Modular Technology of Durkduct Flexible Air Duct System - Reshape the future of Intelligent Ventilation System

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Durkee Flexible Air Ducting System Integrated Solution for New Energy Battery Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Introduction of Fiber Fabric Composite (Insulated) Air Ducts in Automotive Manufacturing Industry

Exposed ventilation duct has the following advantages: post line air apply, lightweight, quick installation and easy maintenance. Durkeesox industrial ac duct system has been widely applied in auto factory, machinery plant, producing plant or logistic warehouse, textile plant, assembly plant, food factory, and cold storage. With the exposed ac duct, the environment is efficiently improved.

The following is our successful cases of industrial air duct.

An Analysis of Common Issues with Durkeesox Fiber Fabric Air Ducts in Cold Storage Design

An Analysis of Common Issues with Durkeesox Fiber Fabric Air Ducts in Cold Storage Design

Three Core Technical Indicators of Fiber Fabric Duct

Three Core Technical Indicators of Fiber Fabric Duct

The Notes for the Installation Process of the Air Ducts

The Notes for the Installation Process of the Air Ducts

The Cloth Air Duct

The Cloth Air Duct

How does the Air Duct Realize the Thermal Insulation?

How does the Air Duct Realize the Thermal Insulation?

The Origin of Durkeesox Ducts

The Origin of Durkeesox Ducts

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية tiếng việt

tiếng việt Svenska

Svenska